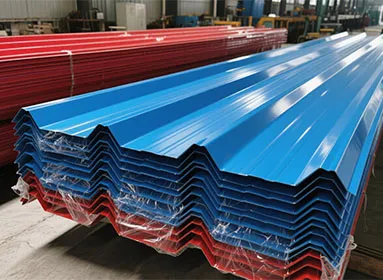

Automatic Color Steel Roll Forming Production Line for Roof and Wall Panels

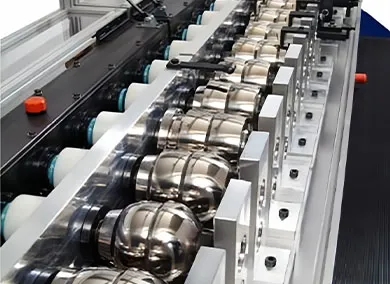

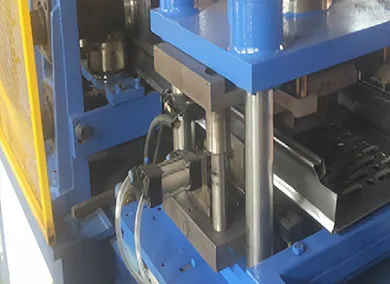

Our color steel sheet and sandwich panel roll forming line is a high-performance solution for producing architectural roofing and wall panels. It supports a variety of color steel profiled sheets—including trapezoidal, corrugated, and antique tile profiles—as well as thermal insulation sandwich panels with EPS, PU, or rock wool cores.