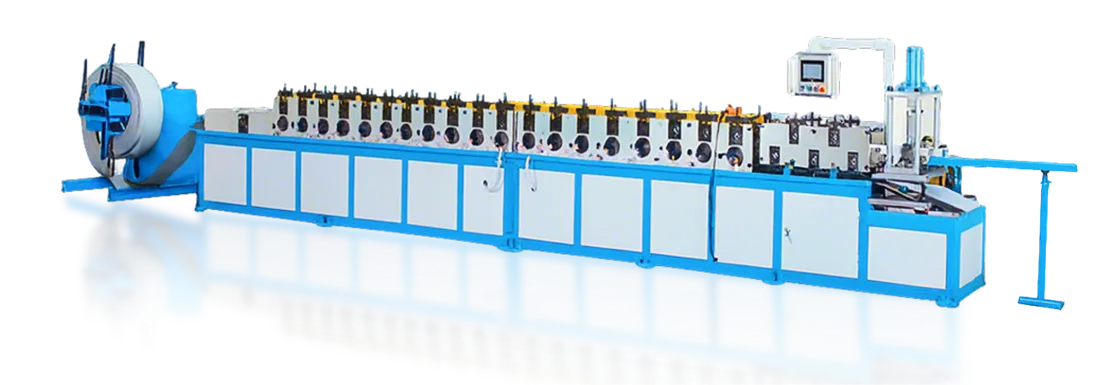

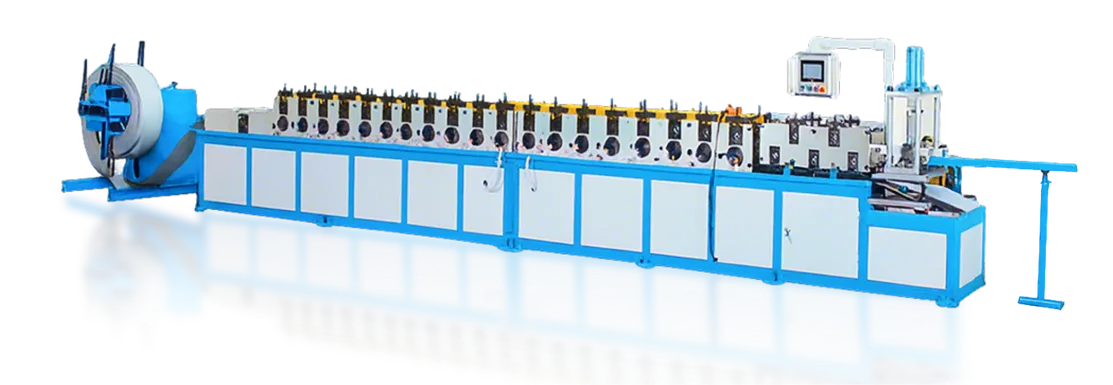

Cold Roll Forming Machines

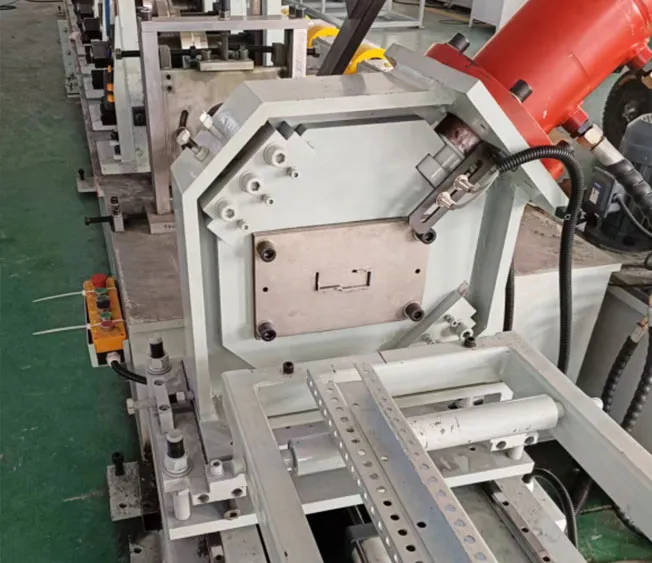

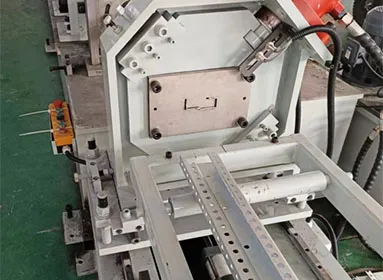

The core device of the entire cold roll forming line (distinct from punching machines). Composed of multiple sets (passes) of forming rolls, it progressively and continuously bends the strip (after leveling and feeding) into the designed cross-sectional shape (such as C-channels, U-profiles, or custom shapes) through sequential rolling. The design, precision machining, and debugging of the forming rolls directly determine the dimensional accuracy, surface quality, and structural stability of the cold-formed profiles, adapting to various metal materials (including stainless steel, aluminum, etc.).