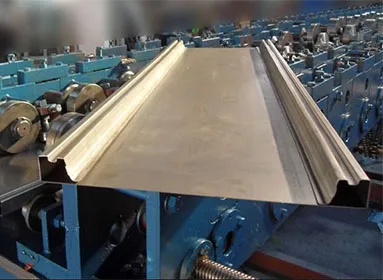

Roll Formed Steel Shelf Laminate Profiles for Light and Medium-Duty Shelving

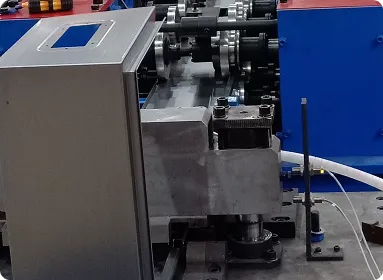

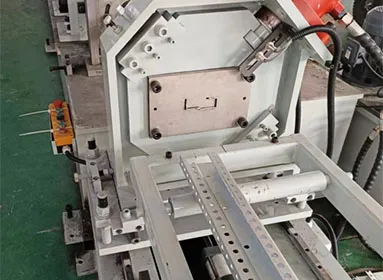

As a specialized manufacturer of cold-formed roll forming machines, we possess mature R&D and production technologies to meet diverse customer product requirements. We are delighted to design and manufacture the profiles you need for applications in construction, automotive, electrical, security, warehousing, transportation, new energy, and other industries.