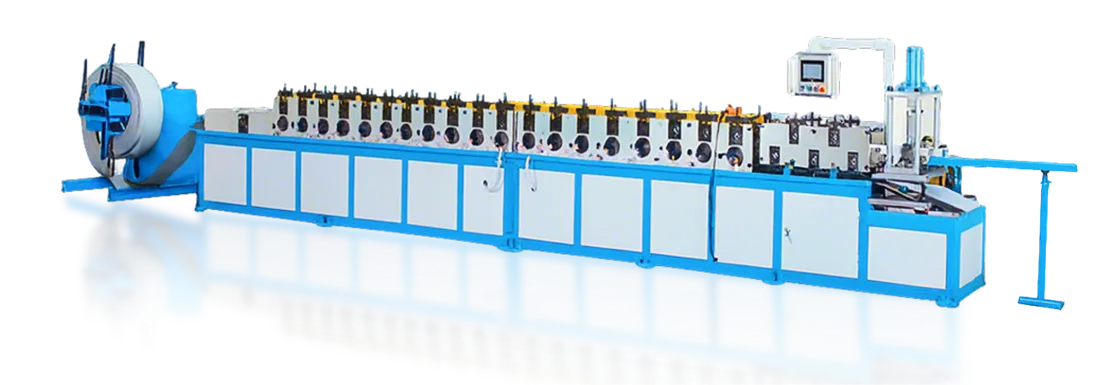

Why Our Machines Stand Out

Advantages Compared to Traditional Production

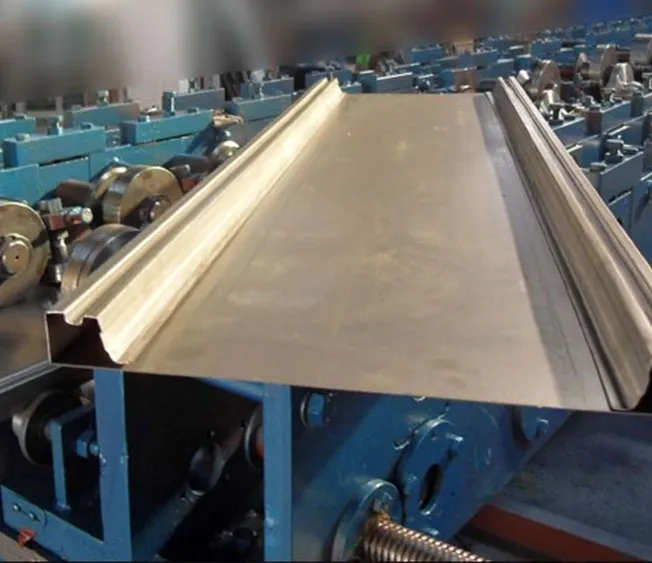

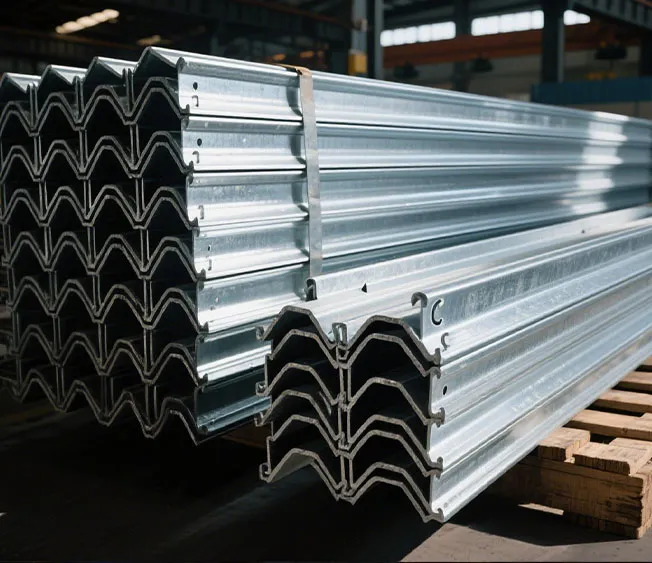

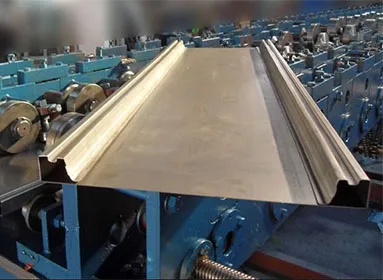

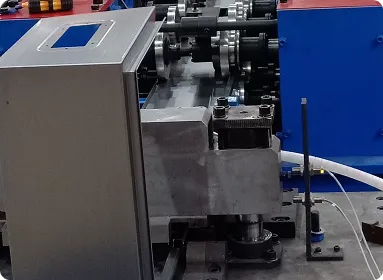

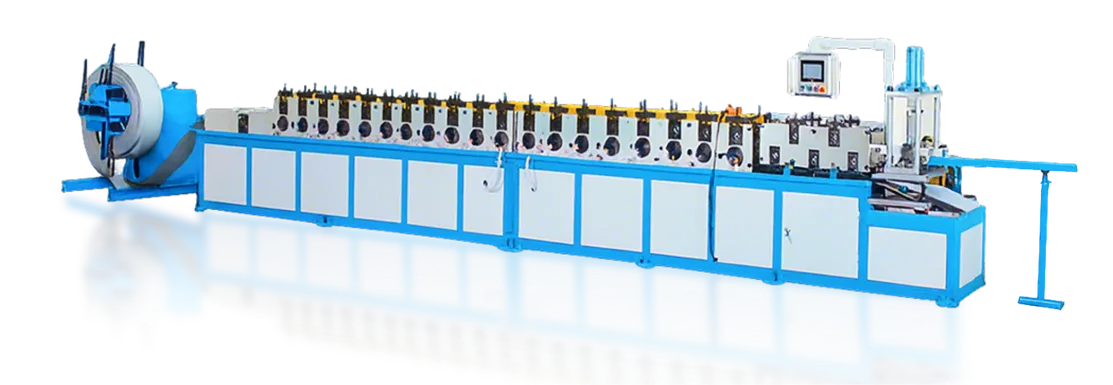

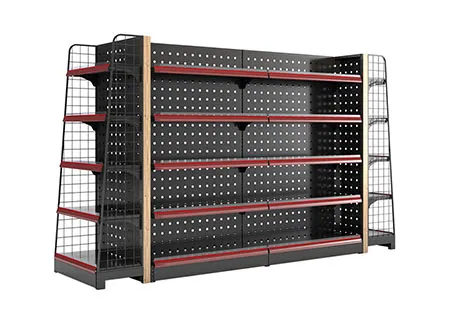

Our light-duty racking production lines are capable of manufacturing a complete range of finished components. These examples demonstrate the precision, flexibility, and quality our machines deliver.

High Precision Profiles

Accurate dimensions for C/Z purlins, cable tray profiles, door/window frames, fire cabinet panels, guide rails, brackets, and custom sections.

Wide Applications

Corrugated panels, roofing sheets, gutters, steel decking, cable trays, distribution box parts, fire cabinet components, dampers, ducts, automotive rails, and non-standard profiles.

Flexible Customization

Custom shapes, thicknesses, materials, punching, and finishes—ideal for custom roll forming and special cross-sections.

High Strength & Stability

Cold forming enhances rigidity and durability for structural and industrial use.

Efficient Production

Continuous roll forming ensures stable quality, low waste, and high output for large-volume profile manufacturing.