Cold-Formed Guide Rails and Channels Profiles for Industrial Applications

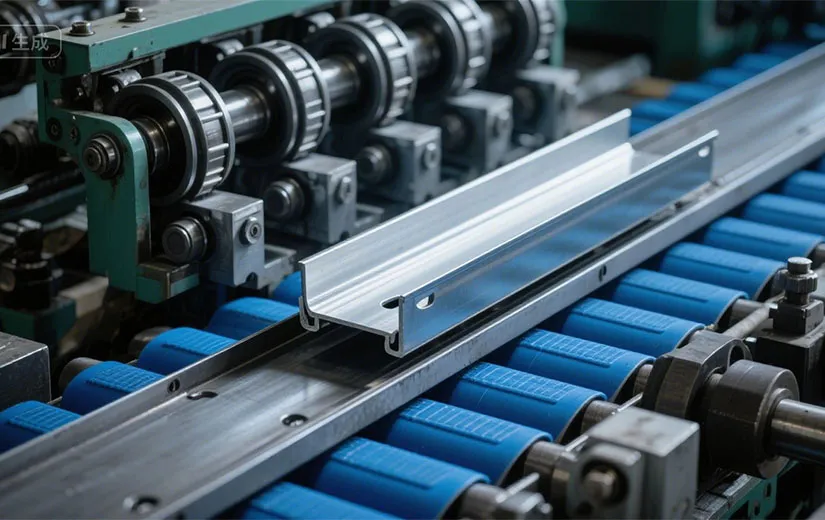

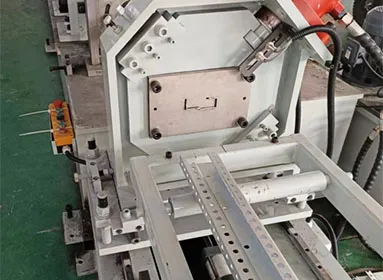

As a manufacturer of cold-forming equipment and non-standard profiles, our automotive products fall into two main categories: dedicated cold-forming equipment for automotive applications (production lines for processing automotive components) and cold-formed profiles and components for automotive use. Our core focus is on critical applications such as door frames, rails, and guide channels, as detailed below: