Ligne de production automatique pour la fabrication de rayonnages d'entrepôt

Les fabricants de rayonnages et d'étagères pour entrepôts sont soumis à une pression croissante en matière de vitesse, de précision et de ...

As global construction and industrial projects continue to expand, manufacturers face increasing pressure to deliver roofing sheets and metal panels with consistent quality, high output, and competitive cost. Traditional forming methods often struggle with low efficiency, unstable accuracy, and high labor dependency. This is where an automatic color steel roll forming production line becomes a decisive solution for modern manufacturers.

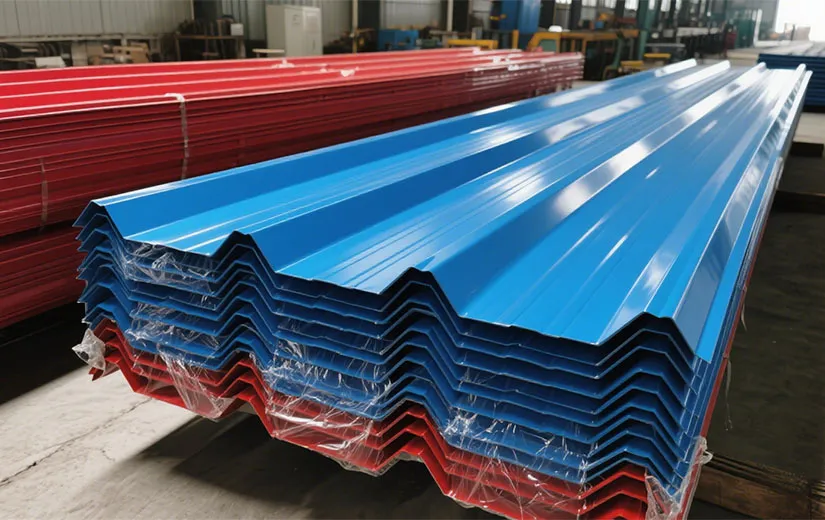

We provide automatic color steel roll forming production lines designed specifically for professional B2B customers who require stable, continuous, and scalable production of color steel roofing sheets, corrugated panels, and metal tiles. Our systems are engineered to convert steel coils into finished profiles through a fully automated roll form process, ensuring precision, efficiency, and long-term reliability.

An automatic color steel roll forming production line is a complete manufacturing system that integrates decoiling, roll forming, hydraulic cutting, and finished product handling into one synchronized production line. From feeding color steel coils to delivering finished roof sheets, the entire process is controlled automatically, reducing manual intervention and improving overall production efficiency.

Our roll forming machine solutions are suitable for processing color steel, galvanized steel, and other coated steel sheets commonly used in metal roofing applications. The roll form process applies gradual and controlled deformation through multiple forming stations, allowing the steel sheet to achieve the desired corrugated, trapezoid, or tile profile without surface damage. This makes the system ideal for producing corrugated roof sheets, metal roofing sheets, and decorative roof tiles with consistent dimensions.

One of the key advantages of our automatic color steel roll forming production line is its high level of automation. The production line integrates a stable decoiler for steel coils, a precision roll forming machine, a hydraulic cutting system for accurate length control, and a receiving table or stacking system for finished products. This automated configuration significantly reduces labor costs while maintaining stable output quality, even during long production runs.

The roll forming machine is the core of the production line. We design our steel roll forming machines with rigid frames, precision-machined rollers made from bearing steel, and optimized forming stations. This ensures smooth roll form operation, minimal vibration, and long service life. For customers producing roofing sheets and metal roof systems for large projects, consistent accuracy is essential, and our equipment is built to meet these demands.

Our automatic color steel roll forming production lines are widely used for producing corrugated roof sheet, roof tile, trapezoid panels, and other metal roof profiles. Corrugated metal roofing is commonly applied in industrial buildings, warehouses, and logistics centers due to its strength and cost efficiency. Tile-style profiles are often chosen for residential and commercial buildings where appearance is a priority. To meet different market needs, we also offer double layer roll forming solutions, allowing two different profiles to be produced on a single machine production line.

Hydraulic systems play an important role in ensuring precise and reliable operation. The hydraulic cutting unit delivers clean, burr-free cuts with accurate length control, which is essential for roofing sheet making and installation. Combined with automatic control systems, the hydraulic components ensure stable performance even at high production speeds.

From a manufacturing perspective, our automatic color steel roll forming production line helps customers improve production efficiency, reduce material waste, and shorten delivery times. Many manufacturers experience a significant increase in output after upgrading from manual or semi-automatic equipment to a full automatic roll forming production line. This improvement allows them to handle larger orders and respond more quickly to project-based demand.

Customization is another core strength of our roll forming solutions. As a professional roll forming machine manufacturer, we understand that different customers require different profiles, materials, and production capacities. We design each color steel roll forming machine according to the customer’s specific requirements, including sheet thickness, profile shape, forming speed, and automation level. This ensures the production line fits seamlessly into the customer’s existing manufacturing workflow.

Our automatic color steel roll forming production lines are trusted by a wide range of B2B customers, including roofing sheet manufacturers, steel structure companies, construction material producers, warehouse and industrial building contractors, and overseas system integrators. These customers rely on our roll forming machinery to support efficient, stable, and scalable production for local and international markets.

Choosing the right supplier for an automatic color steel roll forming production line is critical for long-term success. Beyond machine performance, customers should consider engineering experience, customization capability, and after-sales support. As an experienced roll forming machine manufacturer, we provide not only equipment but also technical guidance, installation support, and long-term service to ensure smooth operation throughout the machine’s lifecycle.

In today’s competitive manufacturing environment, investing in an automatic color steel roll forming production line is not only about increasing output. It is about improving consistency, reducing operational risk, and building a more efficient production system. With reliable roll form technology, advanced automation, and customized design, our solutions help manufacturers strengthen their position in the metal roofing and sheet metal market.

If you are looking to produce high-quality color steel roofing sheets, corrugated panels, or metal tiles with efficiency and confidence, our automatic color steel roll forming production line offers a proven and scalable solution for your business.

Les fabricants de rayonnages et d'étagères pour entrepôts sont soumis à une pression croissante en matière de vitesse, de précision et de ...

De nombreux fabricants d'équipements électriques sont confrontés à des problèmes de qualité des boîtiers, de lenteur...

Nous vous répondrons dans les 24 heures. En cas d'urgence, veuillez ajouter WhatsApp/WeChat : +8613863639320,. Ou appelez directement +8613863639320.

*Nous respectons votre confidentialité et toutes les informations sont protégées.

Nous n'utiliserons vos informations que pour répondre à votre demande et n'enverrons jamais de messages électroniques ou promotionnels non sollicités.