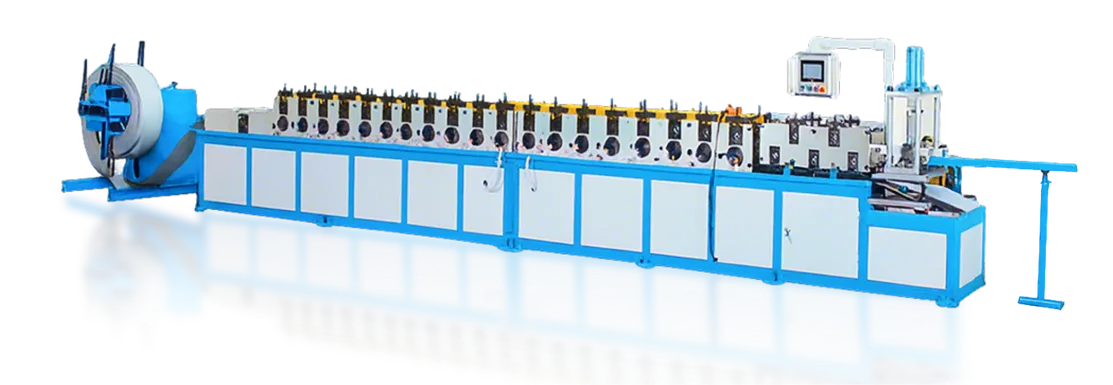

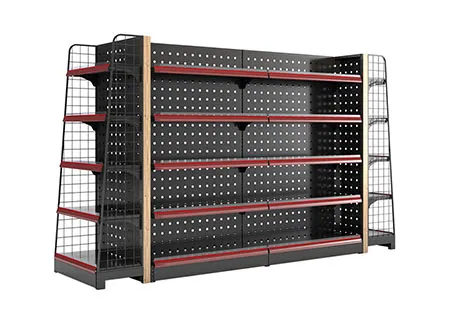

Automatic Production Line for Warehouse and Supermarket Shelving

This equipment can produce shelf decks and uprights in various materials and dimensions to meet different customer requirements. After assembly, they form complete shelving units.

Distribution Box Lines

Cable Tray Production Lines

Cold Roll Forming Production Line

Warehouse Racking Production Lines

Fire Box Production Lines

As a professional manufacturer of cold roll forming equipment and non-standard profiles, we specialize in providing integrated solutions for the electrical industry, covering both custom processing equipment and finished components. Our offerings are tailored to meet the precision, durability, and customization needs of electrical system applications.

Chenlong Intelligent specializes in advanced cable tray roll forming equipment, offering turnkey solutions for both tray-type and ladder-type cable trays. Our high-speed cable tray production line integrates servo feeding, in-line punching, and continuous cold forming—delivering high precision and stability.

This equipment can be customized to produce a wide range of enclosure-type products, including power distribution cabinets, electrical distribution boxes, With strong compatibility and flexibility, the line supports diverse enclosure manufacturing needs, making it ideal for large-scale electrical enclosure and distribution cabinet production.

Our warehouse racking production lines are designed to produce a complete range of components — uprights, shelves, crossbeams, and support braces. With integrated punching, forming, and cutting functions, the lines ensure high efficiency, precision, and cost-effectiveness. Suitable for heavy-duty logistics centers, industrial warehouses, and retail storage systems, they provide the structural strength and flexibility required for modern storage solutions.

It supports various cabinet sizes and types, including wall-mounted and floor-standing models. A modular roller system enables quick profile changes without tool replacement, ensuring high precision and flexible output. The system delivers clean edges and ready-to-assemble shells, reducing manual work and ensuring compliance with fire safety standards.

Discover our most popular roll forming equipment lines, trusted by global clients for their efficiency, precision, and reliability. These machines are widely applied in warehousing, electrical, and construction industries.

CNC control ensures ±0.1mm accuracy.

Machines built with high-strength materials for long lifecycle and reliable operation.

Integrated functions reduce labor and production time.

Supports multiple sizes of uprights and beams without major tooling changes.

Our roll forming equipment and finished profiles are widely applied across

Our light-duty racking production lines are capable of manufacturing a complete range of finished components. These examples demonstrate the precision, flexibility, and quality our machines deliver.

punching, forming, and cutting completed in one continuous process, reducing labor costs by up to 70%.

CNC control guarantees dimensional accuracy within ±0.1mm, ensuring uniform quality across all batches.

adjustable settings allow rapid changeover between different shelf sizes and profiles, meeting diverse order requirements.

built with high-strength materials, our machines are engineered for continuous, long-life operation in industrial environments.

With these advantages, customers can scale up production, shorten delivery time, and stay competitive in the warehousing and storage industry.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +8613863639320,. Or call +8613863639320 directly.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.